Detection of Wheel Misalignment Using Magnetic Sensors

Published:

This project explores a magnetic sensor–based technique for detecting wheel misalignment, focusing on toe and camber angles. Misalignment can affect vehicle performance, safety, and tire wear. Traditional alignment machines are bulky and expensive. This work demonstrates how a compact magnetometer setup can reliably measure misalignments.

Experimental Setup

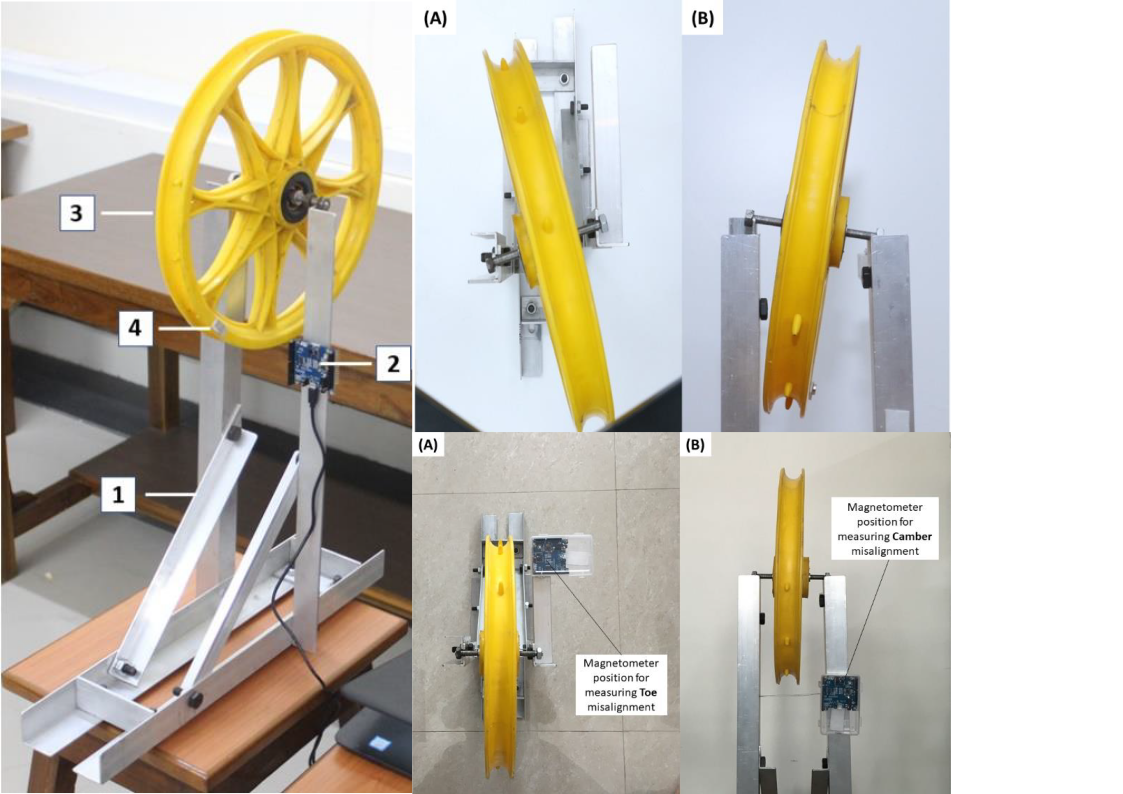

A custom apparatus was developed to hold the wheel and allow controlled misalignment in both toe and camber orientations. A permanent magnet was mounted on the rim while a magnetometer was positioned strategically to capture variations in magnetic flux as the wheel rotated (Fig. 1). The setup allowed repeatable introduction of misalignment angles and real-time data acquisition.

Fig. 1. Experimental setup for measuring toe and camber misalignments.

Magnetometer Calibration

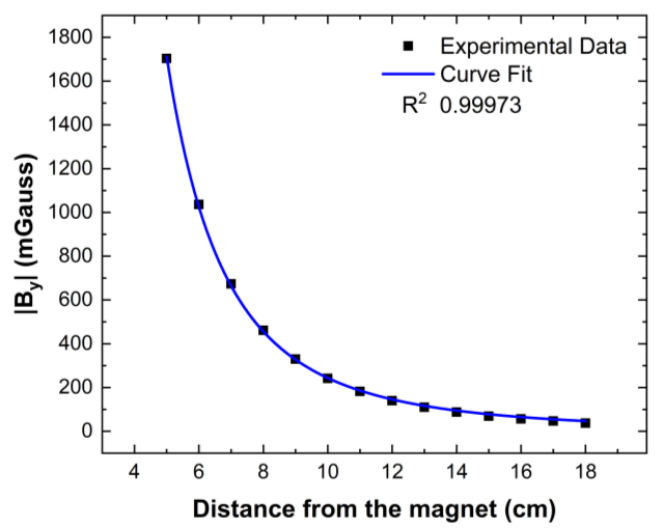

To establish the sensor’s response, the magnetic field was recorded as a function of the distance from the magnet. As expected for a dipole source, the field intensity followed a power-law decay with distance (approximately $B \propto r^{-3}$), and the curve fitting achieved an excellent coefficient of determination of $R^2 = 0.99973$ (Fig. 2).

Fig. 2. Magnetic field decay with distance from the magnet.

Data Acquisition and Signal Features

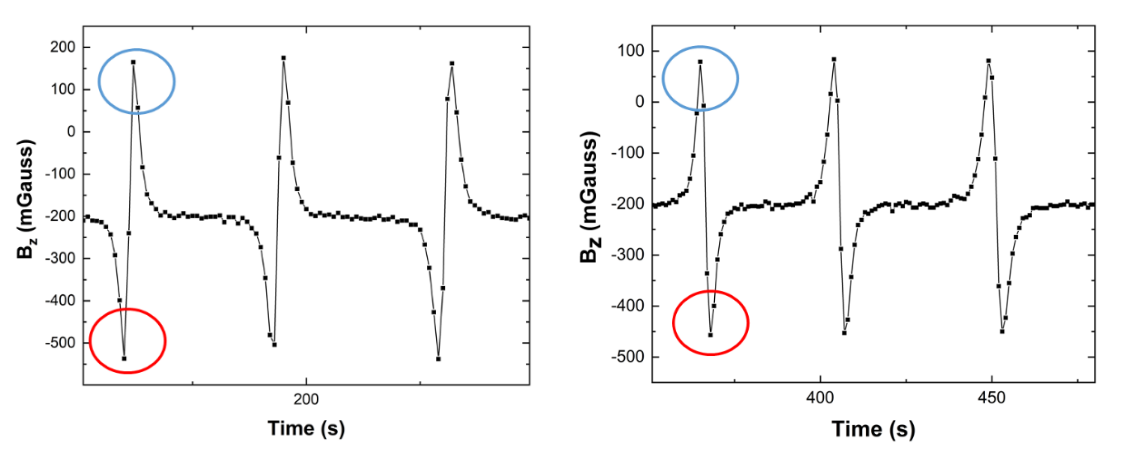

The magnetometer recorded the vertical field component ($B_z$) as the wheel rotated. Distinct positive and negative peaks were observed corresponding to each pass of the magnet near the sensor (Fig. 3). These signal features provided markers for alignment evaluation.

Fig. 3. Time-series signal showing peaks in $B_z$ as the wheel rotates.

Misalignment Detection

By introducing known toe and camber misalignments, clear correlations were established between the misalignment angle and the measured field components. Polynomial fits showed strong agreement with the experimental data (Fig. 4).

- Toe Misalignment: Systematic changes were observed primarily in the lateral in-plane component $B_y$.

- Camber Misalignment: Increasing camber misalignment reduced the vertical component $B_z$ in a predictable fashion.

Fig. 4. Effect of toe and camber misalignments on the measured magnetic field.

Results and Discussion

- The sensor readings demonstrated high repeatability and strong correlation with the imposed misalignments.

- The low-cost setup achieved a sensitivity suitable for detecting even small degrees of misalignment.

- Compared to conventional alignment machines, this system is portable, affordable, and scalable.

Conclusion

This project demonstrated a proof-of-concept for detecting wheel misalignment using magnetic sensors. With further refinement, such systems could enable affordable alignment checks outside specialized workshops, improving vehicle safety and reducing tire wear.

Citation

Harvard Style

Tamhane, D., 2023. Detection of Wheel Misalignment Using Magnetic Sensors. Term project report for CE 720: Non-Destructive Testing of Materials, IIT Bombay. Available at: https://durgeshtamhane.github.io/projects/wheel-misalignment-detection/

BibTeX

```bibtex @misc{tamhane2023wheel, author = {Tamhane, Durgesh}, title = {Detection of Wheel Misalignment Using Magnetic Sensors}, year = {2023}, note = {Term project report for the course CE 720: Non-Destructive Testing of Materials, IIT Bombay}, howpublished = {\url{https://durgeshtamhane.github.io/projects/wheel-misalignment-detection/}} }